Description

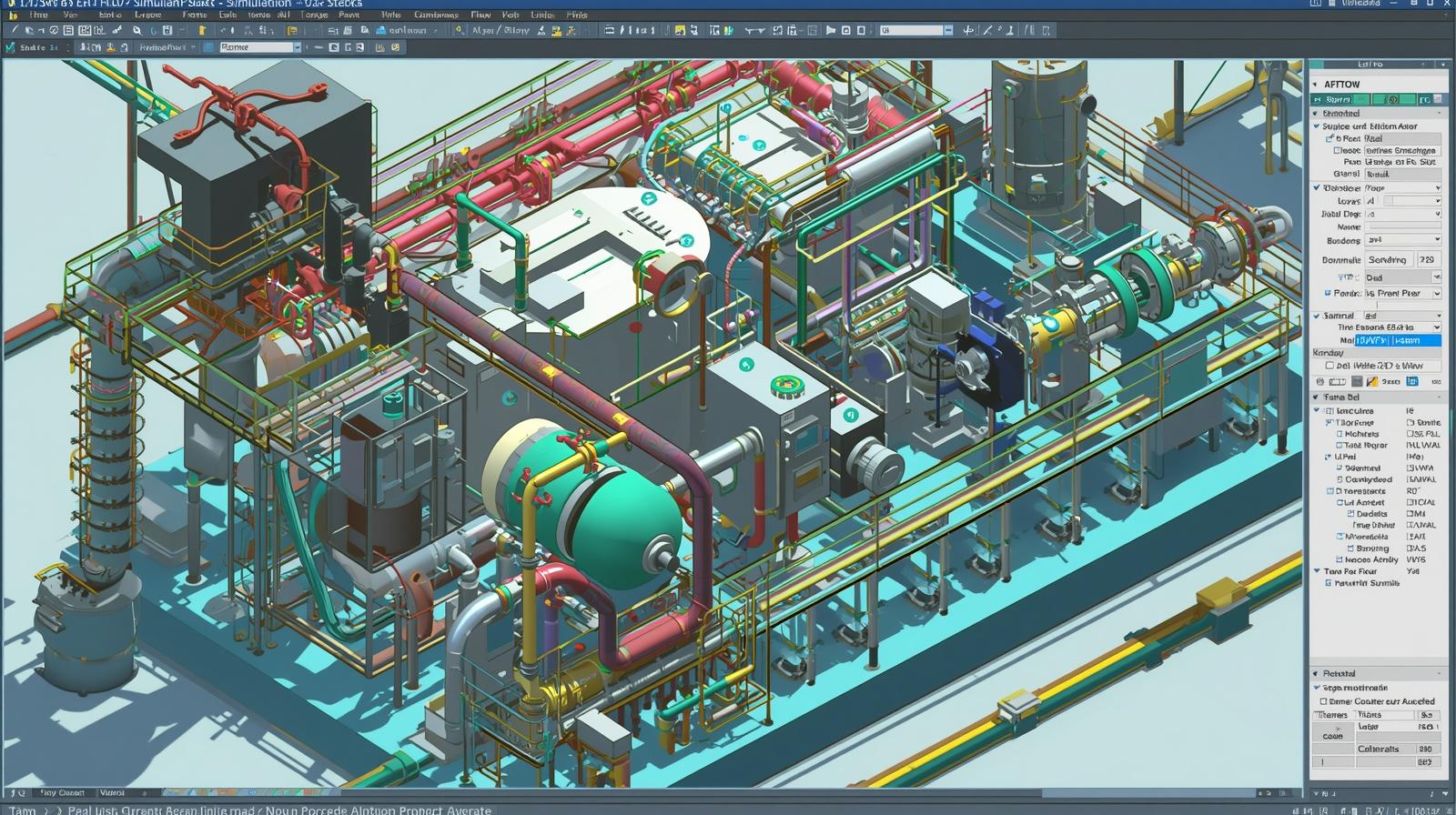

The 3D Plant Modeling Software allows engineers and designers to create detailed, interactive 3D models of oil plants, refineries, and chemical facilities. The software supports layout planning, visualization of equipment, piping, and structural elements, and facilitates workflow optimization. Users can simulate material flow, identify potential bottlenecks, and conduct clash detection to prevent design conflicts. Integrated reporting and analytics enable cost estimation, operational planning, and collaboration among multidisciplinary teams. This tool is ideal for process engineers, project managers, and EPC consultants seeking accurate design representation, improved project efficiency, and enhanced safety planning.

Joseph –

Our team has found the $3D Plant Modeling Software to be instrumental in streamlining our refinery design process. The virtual design tools allowed us to experiment with various layouts and configurations with ease, significantly reducing the time spent on initial planning phases. We especially appreciated the integrated clash detection feature, which identified potential interference issues early on, preventing costly rework during construction. The ability to simulate workflows within the 3D model also provided valuable insights for optimizing operational efficiency before breaking ground, ultimately leading to a safer and more productive facility. The software’s impact on our ability to visualize and resolve issues proactively has been remarkable.

Nazifi –

Our team has significantly streamlined the plant design process using this $3D Plant Modeling Software. The intuitive interface made it easy for our engineers to rapidly prototype different layout options, and the integrated clash detection tools were invaluable in preventing costly rework during construction. The ability to visually simulate workflows and optimize equipment placement before breaking ground has not only saved us time and resources but also improved overall project safety by identifying potential hazards early on. Furthermore, the precise 3D models generated are easily shared with procurement teams, ensuring accurate material requisitions and minimizing delays in obtaining necessary components. This has proven to be a solid investment, delivering tangible improvements to our project efficiency and a safer work environment.

Bitrus –

3D Plant Modeling Software has truly streamlined our design and construction workflows. The intuitive interface made it surprisingly easy to build accurate and detailed 3D models of even our most complex refinery projects. We especially appreciate the integrated clash detection functionality, which has saved us countless hours and prevented costly errors in the field by identifying potential interferences early in the design phase. The ability to simulate different plant layouts and analyze their impact on workflow optimization has been invaluable for improving operational efficiency. Furthermore, the software’s capacity to link model elements directly to procurement databases has significantly enhanced our material management, ensuring timely delivery of the right components to the construction site. The enhanced visualization and realistic simulations fostered by the software have also demonstrably improved safety planning, allowing us to proactively address potential hazards and create a safer working environment for our crews.

Faiza –

3D Plant Modeling Software has significantly streamlined our project workflows. The virtual design tools allowed our team to collaboratively develop and refine plant layouts with unprecedented precision, catching potential spatial conflicts early and avoiding costly rework during construction. The software’s ability to integrate with our procurement system simplified material management, ensuring timely delivery of components to the site. Construction tracking features offered real-time visibility into project progress, facilitating proactive problem-solving and adherence to schedule. Furthermore, the built-in safety features, such as hazard identification and mitigation simulations, have demonstrably improved our safety protocols and reduced potential risks on site. This software is proving invaluable in optimizing plant operations and boosting overall project efficiency.