Description

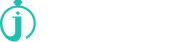

The Remote Equipment Diagnostics Platform allows engineers and technicians to inspect, monitor, and troubleshoot machinery virtually. By leveraging IoT sensor data, high-resolution images, and video feeds, users can assess equipment conditions, identify faults, and recommend corrective actions without being physically on-site. This platform reduces travel costs, accelerates issue resolution, and improves operational continuity. It is suitable for maintenance teams, plant engineers, and technical consultants managing large-scale oil and gas operations.

Imaobong –

The $Remote Equipment Diagnostics Platform has proven to be an indispensable tool for our remote construction sites. Its virtual inspection capabilities allowed us to identify and resolve a critical pump issue weeks ahead of schedule, averting a potentially costly shutdown. The clarity of the video feed, combined with the real-time data overlay from the equipment sensors, enabled our engineers to guide local technicians through the repair process with unprecedented precision. This platform also significantly reduced the need for expensive and time-consuming travel to the site, freeing up valuable personnel for other pressing projects, and ultimately contributing to a more efficient and safer overall project workflow. The remote diagnostics features have drastically improved our proactive maintenance capabilities, allowing us to anticipate and address potential problems before they escalate into major operational disruptions.

Uchechukwu –

Remote Equipment Diagnostics Platform has revolutionized our equipment troubleshooting process. The virtual inspection capabilities are incredibly detailed, allowing our engineers to pinpoint issues on-site without the expense and delays of travel. We’ve significantly improved our operational continuity by using the remote diagnostics features to anticipate potential equipment failures and proactively schedule maintenance. The platform’s detailed imaging and real-time data analysis are invaluable for making informed decisions, and the ability to share findings instantly with our construction and operations teams has streamlined communication and improved overall efficiency. This has demonstrably reduced downtime and optimized our resource allocation, making it an indispensable tool for our EPC projects.

Kasim –

Remote Equipment Diagnostics Platform has truly revolutionized the way we handle equipment troubleshooting on our remote project sites. The ability to conduct virtual inspections with the clarity provided by the platform’s enhanced visual tools allowed us to quickly identify a potential issue with a compressor in a newly commissioned facility, saving valuable time and preventing a costly shutdown. The integrated sensor data streaming alongside the live video feed provided us with the crucial performance metrics needed to accurately diagnose the problem remotely. Furthermore, the seamless integration with our existing maintenance management system facilitated the rapid ordering of replacement parts through its streamlined procurement management capabilities, ensuring a swift return to full operational capacity. The platform’s intuitive interface and robust security protocols also boosted confidence and ensured data integrity throughout the entire diagnostic process.

Abdulrasheed –

The $Remote Equipment Diagnostics Platform has fundamentally altered how we approach equipment troubleshooting in our EPC projects. The virtual inspection capabilities are remarkably detailed, allowing us to pinpoint issues on-site without the expense and delays of physically sending specialists. We’ve significantly reduced downtime on critical equipment thanks to the platform’s remote diagnostic features, enabling our field teams to implement solutions much faster than before. The ability to share live feeds and annotated diagrams with our engineers back at headquarters for collaborative problem-solving has proven invaluable, ensuring everyone is on the same page and contributing to the resolution process. Furthermore, the integrated data logging feature assists in building a comprehensive history of equipment performance, helping us anticipate future maintenance needs and optimize our overall operational efficiency.