Description

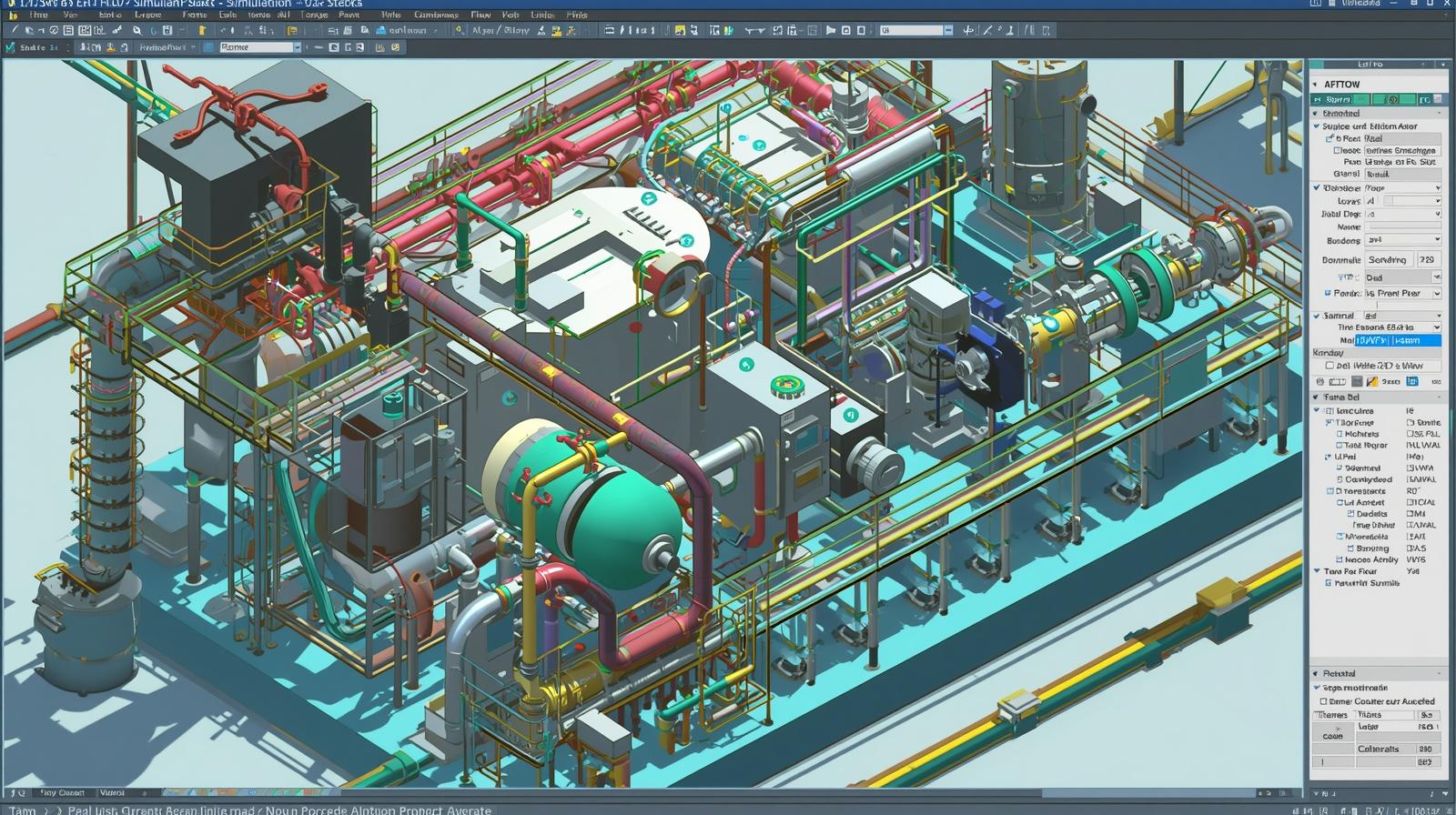

The Process Flow Simulation Software provides engineers with tools to model, analyze, and optimize chemical and oil process workflows. Users can simulate production sequences, energy consumption, equipment utilization, and process efficiency. The software supports scenario testing, bottleneck identification, and process optimization, helping to reduce costs and improve output. Interactive dashboards and reports enable data-driven decision-making. This tool is designed for process engineers, plant managers, and operations teams aiming to maximize efficiency, safety, and profitability in complex industrial processes.

Risikat –

Process Flow Simulation Software has become an indispensable tool for our project teams. The ability to virtually design and analyze complex process flows before committing to physical construction has significantly reduced costly rework and improved overall project timelines. The integrated simulation capabilities allow us to pinpoint bottlenecks, optimize equipment sizing, and fine-tune operating parameters for maximum efficiency. Furthermore, the seamless integration with our procurement management system ensures that material specifications are accurate and readily available, minimizing delays and potential errors in the supply chain. We’ve also leveraged the software’s detailed tracking capabilities to monitor construction progress against the simulated model, providing valuable insights into potential deviations and enabling proactive interventions. The built-in safety analysis features are a particularly strong asset, allowing us to identify and mitigate potential hazards early in the design phase, ensuring a safer working environment throughout the project lifecycle and optimizing operational performance post-commissioning.

Abiola –

Process Flow Simulation Software has been instrumental in streamlining our project workflows; the virtual design tools allowed us to identify potential bottlenecks in the initial design phase, saving significant time and resources further down the line. The integrated simulation capabilities provided concrete data on process efficiency under various operating conditions, enabling us to optimize equipment selection and placement for maximum output. Being able to virtually “walk through” the plant design and identify potential safety hazards before construction even began was invaluable in mitigating risk and ensuring a safer work environment for our teams. Furthermore, the software’s ability to generate detailed material lists and predicted consumption rates has significantly improved our procurement management, minimizing waste and ensuring timely delivery of critical components. Overall, it empowers data-driven operational decisions, leading to tangible improvements in plant performance.

Falmata –

Process Flow Simulation Software has become an indispensable part of my daily workflow. The ability to visually model complex chemical processes and run “what-if” scenarios has drastically improved our team’s efficiency in identifying bottlenecks and optimizing plant performance. The virtual design tools allowed us to pinpoint potential construction issues before even breaking ground, saving significant time and resources in the long run. Furthermore, the integration of real-time data feeds for performance monitoring enables us to proactively adjust parameters and prevent costly downtime, making our operations smoother and more predictable. With its robust simulation capabilities, this software has truly transformed how we approach process optimization and risk mitigation.

Juliana –

Process Flow Simulation Software has significantly streamlined our EPC projects. The virtual design tools allowed us to identify and resolve potential bottlenecks in the proposed oil processing system before physical construction even began, saving considerable time and resources. We were able to input real-world data to simulate different operating conditions and predict potential issues, which helped us optimize the design for maximum efficiency. The software’s seamless integration of procurement management capabilities, particularly the ability to track material lead times and costs within the simulation environment, has been invaluable. Moreover, the detailed flow visualizations and performance reports generated directly from the simulations enabled us to make data-driven decisions, leading to smoother construction phases and improved operational efficiency once the plant went live. It’s a crucial asset for any oil industry professional looking to enhance their process design and execution strategies.