Description

The Predictive Maintenance Software uses AI and machine learning algorithms to analyze equipment performance, identify early warning signs of failure, and schedule maintenance proactively. By predicting machinery issues before they occur, the software reduces unplanned downtime, extends equipment lifespan, and optimizes maintenance costs. Integrated dashboards provide alerts, KPIs, and detailed reports to support informed decision-making. This solution is ideal for maintenance engineers, operations managers, and reliability teams in oil and gas facilities seeking to enhance operational efficiency and equipment reliability.

Haruna –

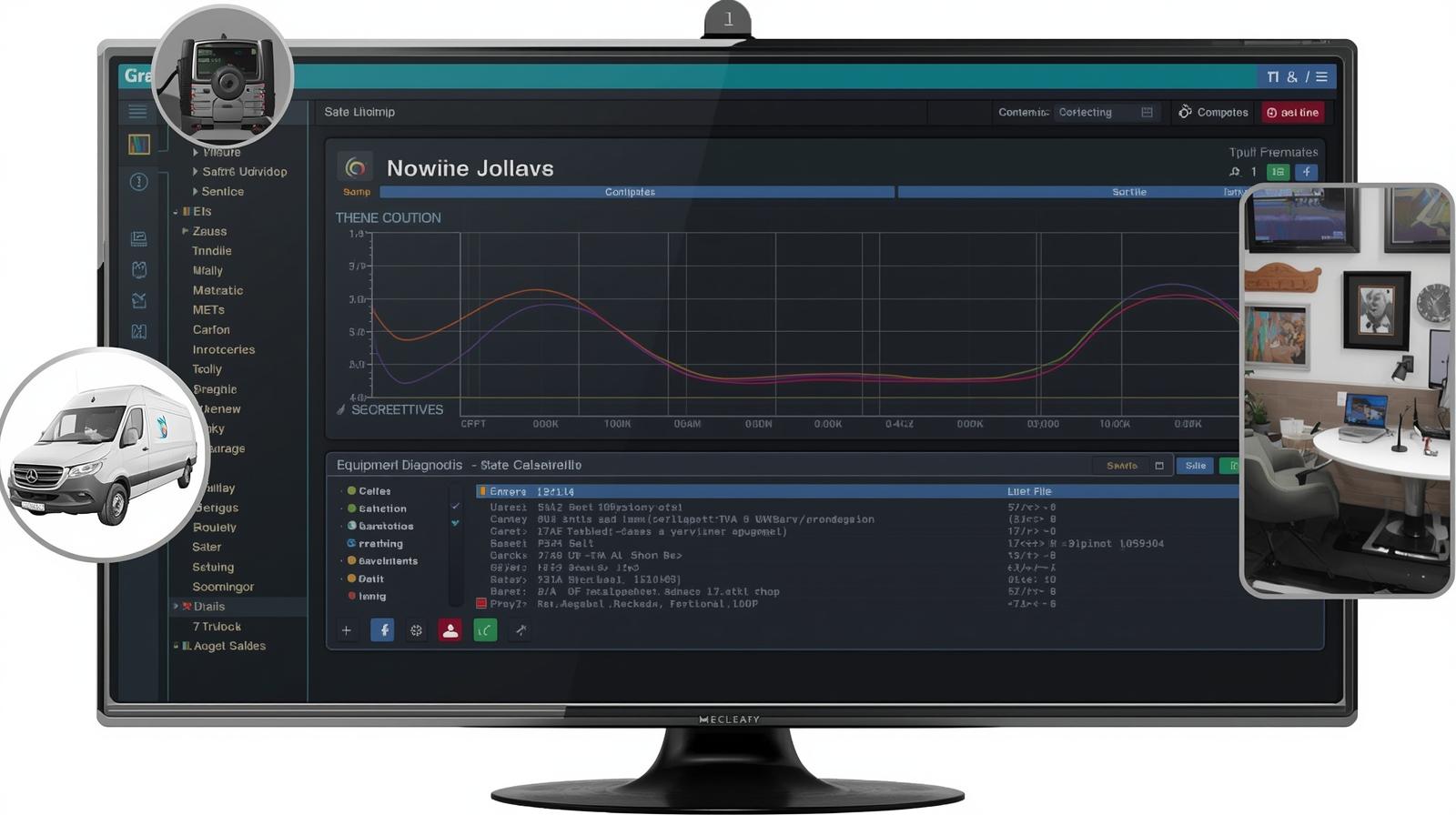

Predictive Maintenance Software has completely transformed our approach to equipment upkeep. The AI-driven insights pinpoint potential machinery failures weeks in advance, allowing us to schedule maintenance proactively instead of reacting to costly breakdowns. Specifically, the visualization dashboards make it incredibly easy to understand the predicted failure timelines and identify critical components needing attention. This has significantly reduced unexpected downtime on site, letting us stay on schedule and within budget. The integrated reporting features also streamline our maintenance planning meetings, providing concrete data to justify resource allocation and prioritize critical tasks. Ultimately, this tool has helped us optimize operational reliability and minimize disruptions across our entire EPC project lifecycle, translating directly to increased profitability and reduced risk.

Christiana –

Predictive Maintenance Software has truly transformed our approach to equipment upkeep within our EPC projects. The AI-driven insights allow us to foresee potential machinery failures weeks in advance, giving us ample time to schedule maintenance during planned downtime rather than reacting to costly, unexpected shutdowns. We’ve seen a significant reduction in operational interruptions and a marked improvement in overall project efficiency since implementing the software. The ability to pinpoint specific components at risk, coupled with the software’s integration with our procurement management system, means we can order replacements proactively, avoiding delays associated with emergency sourcing. Furthermore, the visual dashboards provide clear and concise summaries of equipment health, enabling our field teams to prioritize maintenance tasks effectively and ensuring a safer, more reliable operating environment on-site.

Raymond –

Predictive Maintenance Software has been a significant asset in streamlining our oilfield operations. The AI-driven predictive capabilities have allowed us to transition from reactive repairs to proactive maintenance, substantially reducing unexpected downtime. We’ve seen a noticeable improvement in operational reliability thanks to the software’s ability to accurately forecast machinery failures well in advance, giving us ample time to schedule maintenance and procure necessary parts without disrupting production. The visualization tools integrated within the platform are particularly useful, providing clear and concise insights into potential equipment issues that would have been difficult to detect otherwise. This targeted approach has also translated into cost savings through optimized resource allocation and minimized emergency repairs.