Description

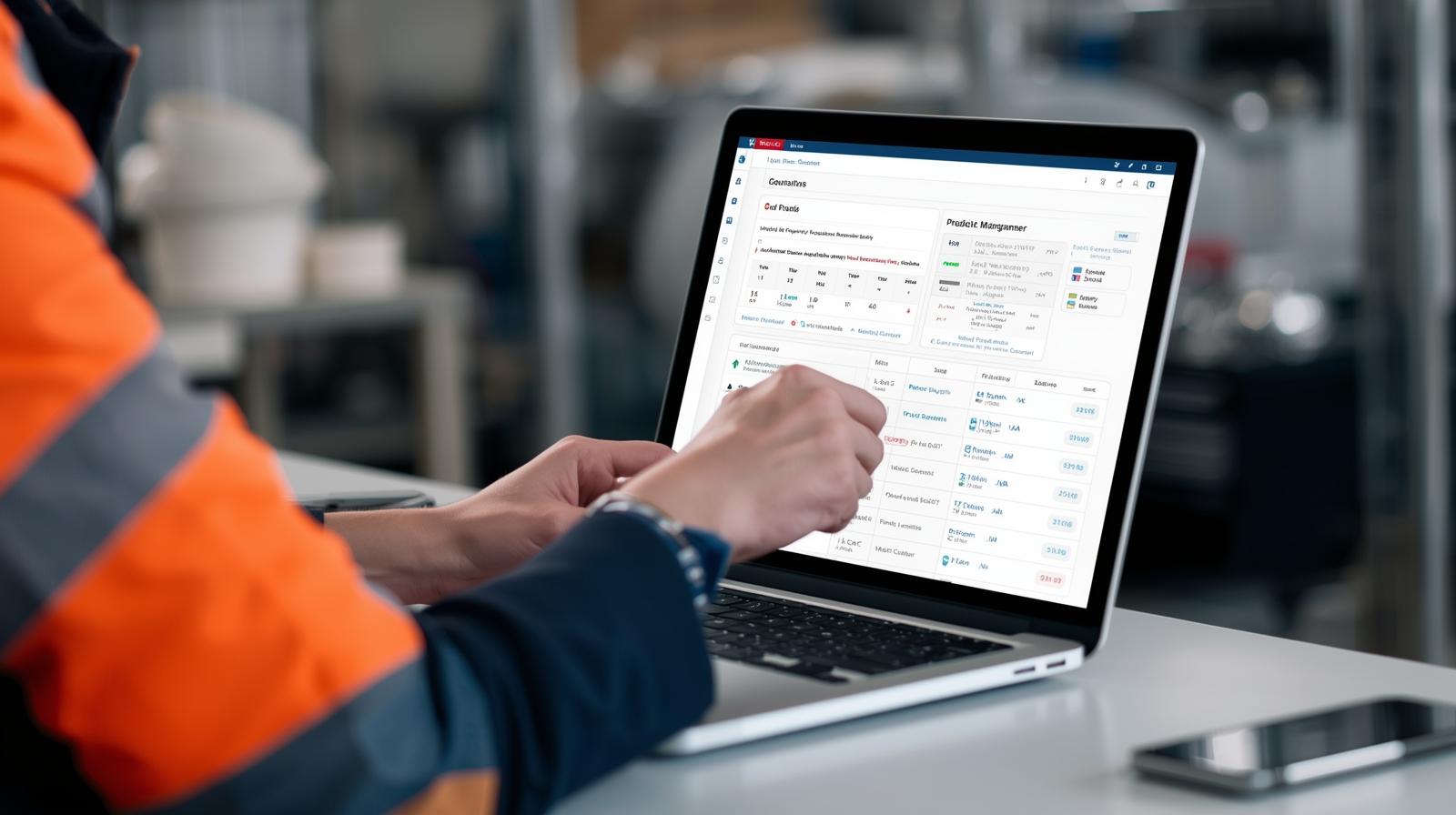

The Digital Twin of Oil Facilities is a virtual replica of oil and gas plants that enables real-time monitoring and simulation of operations. The platform integrates sensor data, equipment status, and process metrics to provide a comprehensive overview of facility performance. Users can simulate process adjustments, evaluate operational efficiency, and predict potential failures without affecting live systems. This tool supports operational decision-making, safety management, and performance optimization. It is ideal for plant operators, engineers, and facility managers aiming to improve operational visibility, reduce downtime, and enhance safety compliance.

Auwalu –

Working with the $Digital Twin of Oil Facilities has completely transformed our approach to projects. The integrated virtual design tools allowed us to visualize potential construction challenges before even breaking ground, saving significant time and resources. Procurement management became remarkably streamlined thanks to the real-time inventory tracking and automated supplier communication features. We’ve also seen a substantial improvement in safety training; the simulations within the Digital Twin provided our field teams with invaluable experience in handling emergency scenarios within a controlled, virtual environment. Furthermore, the ability to monitor operational performance and predict potential equipment failures has allowed us to proactively address maintenance needs, maximizing uptime and optimizing production efficiency.

Uduak –

The $Digital Twin of Oil Facilities has revolutionized how we approach project planning and execution. The immersive 3D environment allows our engineering teams to collaborate on design changes in real-time, eliminating costly rework down the line. We’ve leveraged the procurement management features to streamline vendor communication and track material delivery with unparalleled accuracy, resulting in significant time savings. During the construction phase, the real-time tracking and progress monitoring capabilities proved invaluable for staying ahead of schedule and identifying potential bottlenecks before they impacted critical timelines. Furthermore, the integrated safety features and scenario simulations gave our operations team the ability to proactively identify and mitigate risks, ensuring a safer working environment for everyone on site. The ability to simulate different operational scenarios and optimize performance based on predictive insights has already translated into measurable improvements in facility efficiency.

Chuks –

Using the $Digital Twin of Oil Facilities has completely transformed our approach to project execution. The interactive virtual design tools allowed our engineers to identify and resolve clashes virtually, saving significant time and resources during the physical build. Procurement management capabilities within the platform offered real-time visibility into material availability and potential delays, enabling proactive adjustments to the schedule. Furthermore, the construction tracking feature, coupled with the integrated safety protocols within the digital twin, enhanced site safety and efficiency simultaneously. The ability to simulate various operational scenarios and gain predictive insights has proven invaluable for optimizing facility performance and minimizing downtime long after commissioning, making it a truly indispensable asset throughout the project lifecycle.

Dare –

The $Digital Twin of Oil Facilities has fundamentally improved how we approach EPC projects. The integrated virtual design tools allowed our engineering team to collaboratively refine the plant layout and identify potential clashes far earlier in the process than with traditional methods, saving significant rework time and cost. Procurement management is now streamlined with real-time inventory tracking within the digital twin, enabling us to anticipate material shortages and optimize delivery schedules. Moreover, the construction tracking features have provided unparalleled visibility into project progress, allowing for proactive issue resolution and minimizing delays. The safety features embedded within the simulation capabilities are exceptional; we can now virtually rehearse complex procedures and identify potential hazards before anyone even steps foot on site, leading to a much safer work environment. Finally, the operational optimization features empower our clients with predictive insights, helping them anticipate maintenance needs and maximize production efficiency long after construction is complete, adding significant value to our completed projects.